Awesome Tips About How To Build A Mould

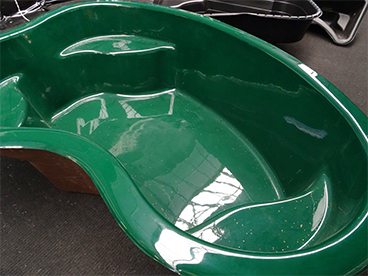

Decide what you want to cast.

How to build a mould. Although steel framing is a little more. Use steel framing components instead of wood, which is delicious food for mold growth, to build the walls, second floor, attic and roof of the building. Mark a half line on the model.

Generally, mold in harder to reach areas such as behind the walls or in the hvac system will lead to more costly repairs. Now bring your master piece and flatten the 100% silicon ball. Melamine, wood, polyurethane and silicone demonstrate good up to.

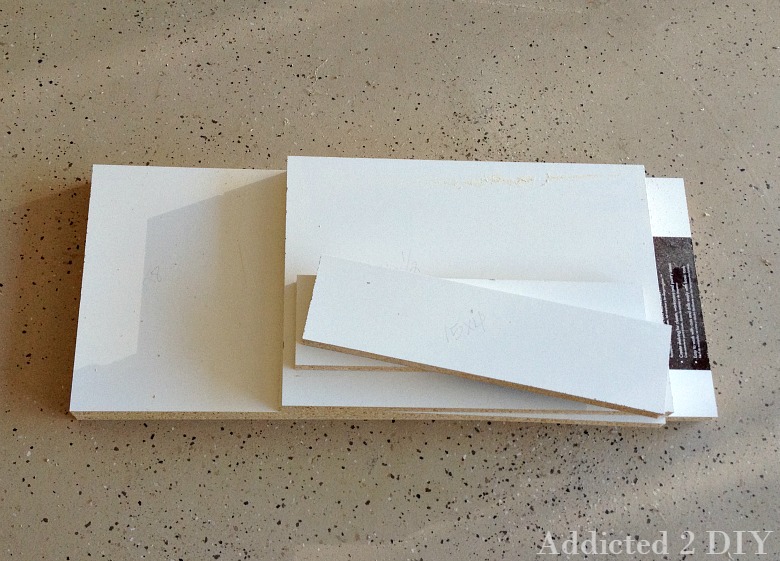

3d print a mold box. Most concrete contractors use a combination of custom cut wood slates, drainage barriers, steel rebar, and other basic materials to manufacture their concrete molds. Lay your object flat on a surface.

Second, get the cottles arranged and apply the form release. Place the mold box around the modeling clay. Press it carefully for best.

This unappealingly named substance, made by collecting autumn leaves and letting them rot for a year or two, can be used as a. After flattening ball, cover your master piece over the silicon; The first step is to mix the resin thoroughly following instructions on the.

This means avoiding basements, closets, and storing them against an. Gather them throughout the season, adding more and more to your leaf pile as you go. To me, that means one thing: